Top 8 Vulnerability Management Tools

Explore the best VRM software to streamline due diligence, monitor vendors in real time, and support compliance, reporting, and business continuity.

Published on October 27, 2025

Last updated on January 07, 2026

Manufacturing operations face increasing risks due to supply chain dependencies, cybersecurity threats, equipment failures, and shifting regulatory standards. While traditional risk management tools focus on identifying and recording threats, modern risk and resilience software—especially those incorporating Security Orchestration, Automation, and Response (SOAR) capabilities—enables manufacturers to respond faster and recover stronger.

These systems automate incident response, enhance visibility across facilities, and align with operational resilience frameworks like ISO 22301 and NIST SP 800-61. From predictive analytics to automated reporting, the right software can transform how manufacturers safeguard productivity, compliance, and supply chain stability.

Let’s look at what risk and resilience software actually is, the key features to consider, and the best solutions available for 2026.

Risk and resilience software combines risk management, incident response, and business continuity tools into a unified platform designed to maintain manufacturing uptime. It provides structured frameworks for identifying, assessing, mitigating, and monitoring operational risks, while embedding resilience practices into daily operations.

When integrated with SOAR capabilities, such platforms automate routine security and operational workflows—collecting data, executing predefined responses, and escalating issues in real time. The result is not just risk awareness but automated resilience, where systems anticipate and respond to disruptions before they impact production or compliance.

A strong platform should unify automation, visibility, and compliance. Here are the essential features to prioritise:

Allows users to catalogue and evaluate operational, cyber, and supply chain risks. Look for support for both qualitative and quantitative assessments using configurable risk matrices.

Automates repetitive security and response tasks. Playbooks trigger preapproved actions—such as isolating affected systems or notifying plant teams—reducing downtime and manual intervention.

Provides structured workflows for logging, tracking, and resolving incidents. In manufacturing, this may include quality deviations, equipment failures, or cyber breaches.

Enables creation, testing, and execution of recovery plans aligned with ISO 22301 or similar standards to ensure production continuity after incidents.

Tracks regulatory obligations, audit findings, and corrective actions to demonstrate adherence to frameworks like ISO 27001, NIS2, and local safety regulations.

Consolidates data across sites and systems to present live operational status, KPIs, and resilience indicators in visual dashboards.

Integrates with manufacturing execution systems (MES), ERP, and SCADA environments for end-to-end visibility, and scales as operations expand globally.

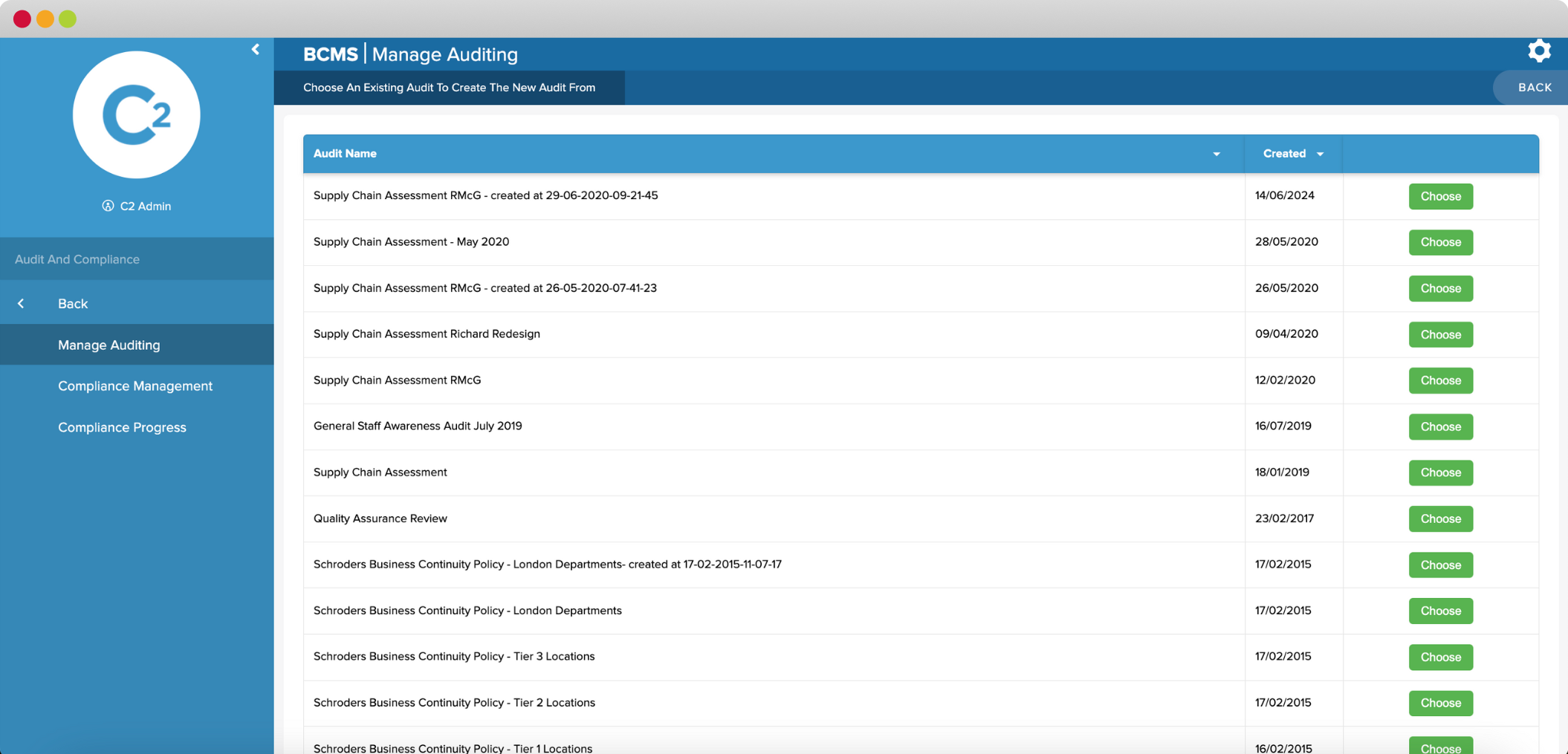

Continuity2 leads with its Meridian platform, an industry-leading solution built for enterprise-level business continuity and operational resilience. It enables manufacturers to automate the full risk lifecycle—identification, assessment, response, and recovery—while maintaining compliance with ISO 22301 and related standards.

Its modular design supports risk registers, real-time dashboards, automated alerts, and response workflows, empowering users to act immediately on disruptions. Meridian’s data-driven insights allow plant managers to strengthen supply chain resilience and streamline audits across multiple sites.

Key Features:

Best for: Large manufacturing enterprises seeking an end-to-end resilience automation solution.

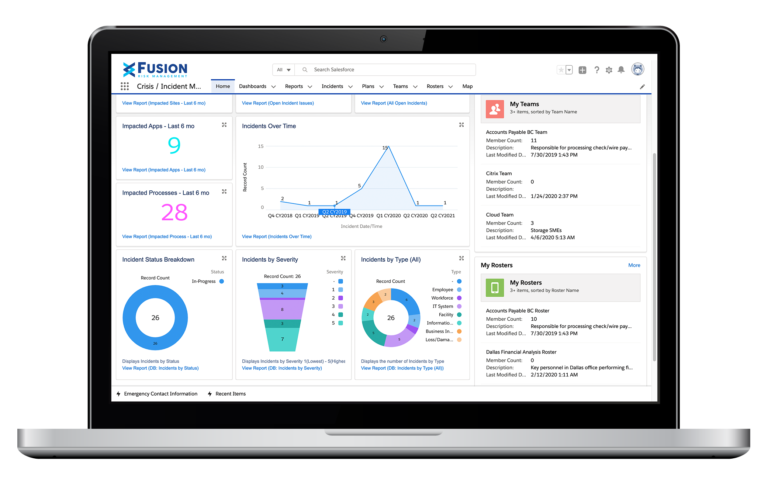

Fusion offers a configurable resilience platform that supports risk, continuity, and incident response in one environment. Its automation engine enables proactive monitoring of operational dependencies and supply chain vulnerabilities.

Key Features:

Best for: Manufacturers with complex, global supply chains.

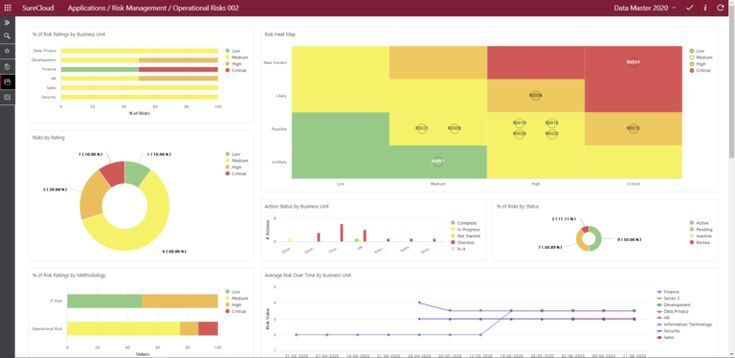

SureCloud delivers integrated risk, resilience, and compliance capabilities. It provides a unified interface for identifying, mitigating, and monitoring manufacturing and cybersecurity risks while automating workflows for incident handling.

Key Features:

Best for: Mid-sized manufacturers seeking balance between usability and depth.

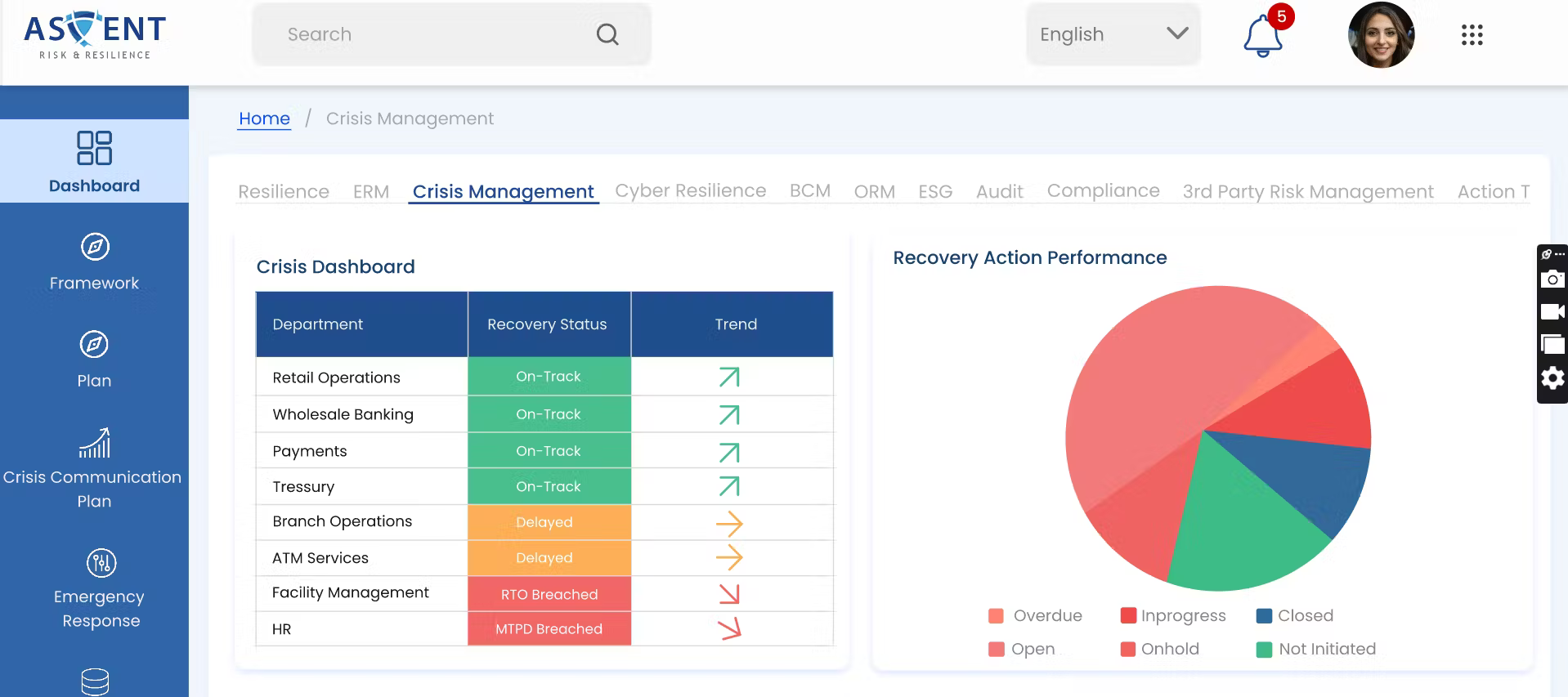

Noggin provides an operational resilience and crisis management suite tailored for high-reliability industries. It merges risk management, incident response, and communications under one platform, supporting real-time situational awareness.

Key Features:

Best for: Manufacturers requiring mobile-first crisis coordination tools.

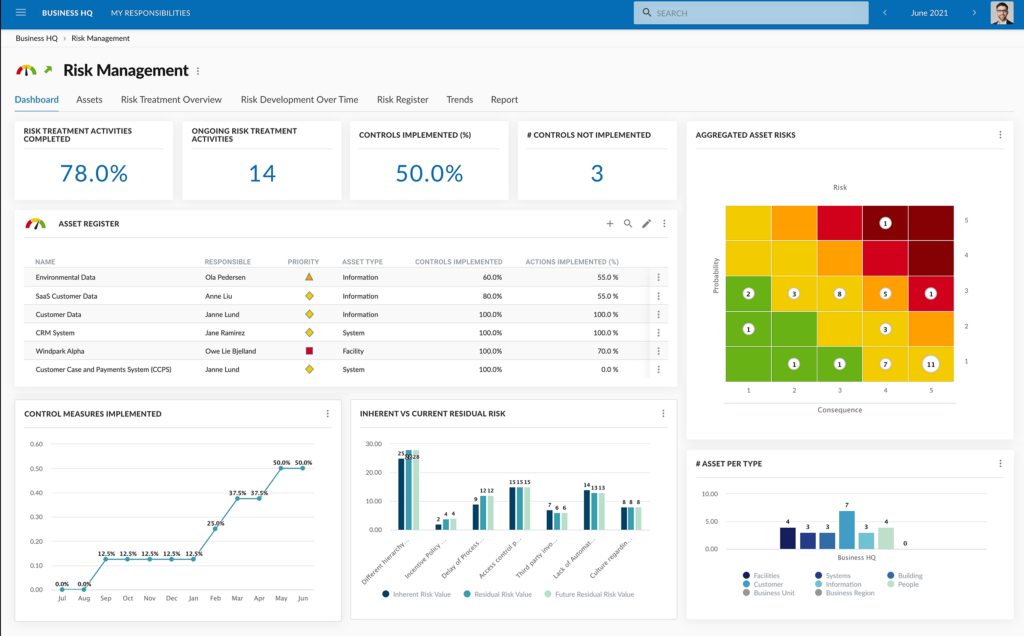

Corporater’s configurable system aligns with ISO and COSO frameworks, enabling governance-driven resilience programs. It integrates risk analytics, KPIs, and incident workflows across multiple plants or regions.

Key Features:

Best for: Organisations prioritising governance-led resilience.

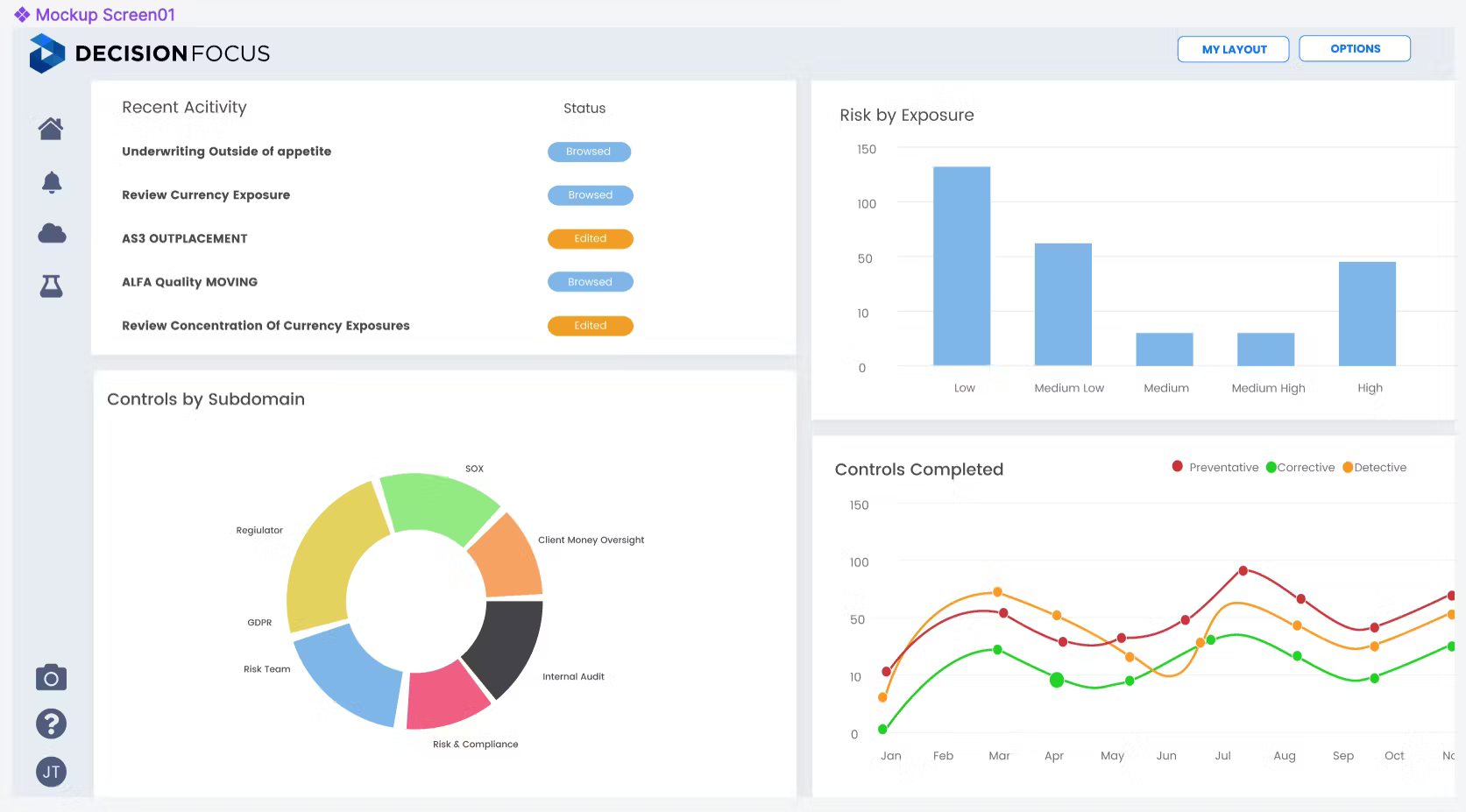

Decision Focus provides a cloud-based operational resilience platform with built-in SOAR integration. It automates incident triage and response while tracking control effectiveness and audit outcomes.

Key Features:

Best for: Manufacturers needing compliance automation with minimal manual effort.

AutoResilience specialises in predictive maintenance and automated recovery in manufacturing environments. Using AI and machine learning, it integrates SOAR capabilities to trigger corrective maintenance before failures escalate.

Key Features:

Best for: Manufacturers focused on predictive risk and maintenance automation.

Operational resilience software for manufacturing empowers organisations to automate responses, enhance visibility, and maintain continuity across complex production environments.

Automation drastically reduces manual intervention. By leveraging SOAR playbooks, manufacturers can contain incidents or trigger recovery procedures within minutes, minimising production losses.

Centralised dashboards offer a unified view of operational risks, enabling leadership to make informed, evidence-based resilience decisions across global facilities.

Automated evidence collection and workflow documentation simplify compliance with international standards, making audits smoother and more transparent.

With integrated monitoring, manufacturers can quickly identify and mitigate supplier or logistics disruptions, maintaining operational stability.

Embedding risk awareness and automated response within daily workflows encourages proactive resilience and continuous improvement across teams.

Resilience in manufacturing is no longer optional—it’s a strategic imperative. As automation and interconnected operations increase exposure to cyber, operational, and supply chain risks, integrated risk and resilience software helps you stay ahead of disruptions.

Continuity2’s Meridian platform provides the automation, visibility, and control needed to safeguard uptime, simplify compliance, and strengthen operational resilience across every manufacturing site.

Book a Demo with Continuity2 to see how Meridian can transform your organisation’s resilience strategy and build a more connected, disruption-ready operation.

Founder & CEO at Continuity2

With over 30 years of experience as a Business Continuity and Resilience Practitioner, Richard knows the discipline like the back of his hand, and even helped standardise BS25999 and ISO 22301. Richard also specialises in the lean implementation of Business Continuity, IT Service Continuity and Security Management Systems for over 70 organisations worldwide.

Founder & CEO at Continuity2

With over 30 years of experience as a Business Continuity and Resilience Practitioner, Richard knows the discipline like the back of his hand, and even helped standardise BS25999 and ISO 22301. Richard also specialises in the lean implementation of Business Continuity, IT Service Continuity and Security Management Systems for over 70 organisations worldwide.

Explore the best VRM software to streamline due diligence, monitor vendors in real time, and support compliance, reporting, and business continuity.

Explore the best VRM software to streamline due diligence, monitor vendors in real time, and support compliance, reporting, and business continuity.

Discover the top 10 Threat Intelligence Platforms of 2026 to detect, analyse, and respond to cyber threats with greater speed and precision.

Explore the best third-party risk management software to automate vendor assessments, track compliance, and reduce exposure across your supply base.

Discover the top 7 Supply Chain Risk Management (SCRM) tools of 2026 to monitor suppliers, predict disruptions, and build supply chain resilience.

Find the best supply chain management software of 2026 and gain real-time visibility, streamline planning and logistics, and protect business continuity.

Compare the top supplier monitoring tools of 2026 and find the right software to enhance supplier visibility and protect your supply chain.

Find the best SIEM tools to detect threats faster, automate incident response, ensure compliance, and strengthen your organisation’s cyber resilience.

Choose the right risk analysis software to automate assessments, gain real-time insights, meet compliance, and strengthen resilience—see our top 7.